Product Specification | TD Cladding Supplies PTY LTD

About Us

Whether for your commercial or residential property, TD Cladding Supplies Pty Ltd is the company to rely on for all your cladding needs.

Combining our highly skilled workforce with the latest equipment and finest materials, our experts deliver design and installation services tailored to your exact requirements.

Moreover, we pride ourselves on our outstanding craftsmanship and ability to handle any type of project, big or small!

We can handle any type of project

Product Specifications

TD Cladding Supplies Pty Ltd offers a wide variety of aluminum composite panels and aluminum honeycomb panels with more than 30 standard colours to choose from. Our installation team will be able to meet any of your unique requirements.

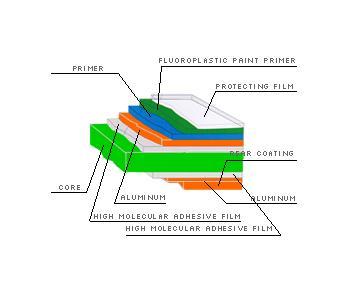

Aluminum composite panels are composed of a polyethylene core sandwiched between two sheets of aluminum. The surface of the panel is covered with a protective peel off foil. Outdoor aluminum plastic composite panels are coated with fluorocarbon (PVDF) on the surface, while indoor aluminum composite panels are coated with polyester.

Product Characteristics:

- Light weight, high intensity, and easy to maintain, cut, bend, arch and install. The panel average weight is 3.5 – 5.5 kg/sqm

- Extremely good resistance against weather, acidity and alkaline, great thermal insulation, acoustic insulation and damping

- The surface is dust-proof treated, smooth, flat and easy to maintain; just a neutral cleaner with water can totally renew the panel

- The aluminum surface is tough and the core PE panel is flexible to give the panel high impact resistance

- Fireproof and noise absorptive (the PE core absorbs noise and the aluminum resists fire)

Specifications

TD Cladding Supplies Pty Ltd offers installation and technical support for aluminum composite panel (ACP) and aluminum honeycomb panel AHP). The following is a guideline to processing aluminum composite panels.

| Standard Sizes | Thickness | Non-Standard Sizes | Colour |

|---|---|---|---|

| 2400 x 1250 mm 3000 x 1250 mm 3600 x 1250 mm 4200 x 1250 mm |

For interior use: Thickness: 3 mm For exterior use: Thickness: 4mm – 10mm |

Available upon request | There are more than 30 different colours to choose from, but we can also match your colour requirements. |

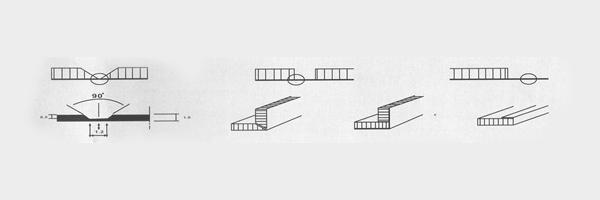

Panel Processing

| Section Drawing | Processing Method |

|---|---|

|

Slotting: Slot the back and then bend |

|

Cutting: Panel can be cut by suitable kinds of saws and lathes |

|

Fixing: Fix the panel with angle aluminum by rivet or screw |

|

Bending: Panel can be bent by bending brake to get the ideal arc |

Aluminum Composite Panel Installation

| Installation methods | Section drawing | Installation methods | Angel and Seal |

|---|---|---|---|

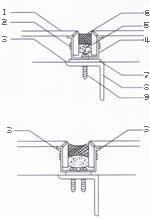

| Angel and Seal: |  |

External Panel: |  |

| 1. Panel | 1. Panel | ||

| 2. Rivet | 2. Sealer | ||

| 3. Angel Aluminum | 3. Padding | ||

| 4. Angel Aluminum | 4. Angel Steel | ||

| 5. Padding | 5. Steel plate strip | ||

| 6. Silicon sealant | |||

| 7. Spacer | |||

| 8. Screw | |||

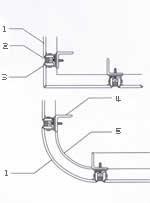

| Column: | Internal Corner: | ||

| 1. Panel |  |

1. Panel |  |

| 2. Angel support | 2. Sealer | ||

| 3. Steel strip | 3. Padding | ||

| 4. Sealer | 4. Steel angel | ||

| 5. Padding | 5. Bullen screw | ||

| 6. Bullen screw | |||

| 7. Bearing strut | |||

| 8. Steel angel | |||

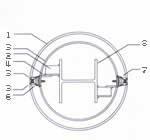

| Joint of Ceiling: | Pillar: | ||

| 1. Panel |  |

1. Panel |  |

| 2. Building top | 2. Angel support | ||

| 3. Angel support | 3. Angel steel | ||

| 4. Angel support | 4. Sealer | ||

| 5. Steel angel | 5. Padding | ||

| 6. Sealer | 6. Plastic lining bar | ||

| 7. Padding | 7. Bullen screw | ||

| 8. Bullen screw | 8. Bearing strut | ||

| 9. Built-in anchor or expanding bolt | |||

Aluminum Honeycomb Panel – Rydalmere (NSW)

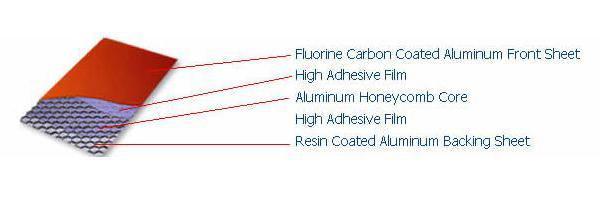

Aluminum honeycomb panels combine the advantages of aluminum panels with aluminum plastic panels and overcome the disadvantages of single aluminum panels or aluminum composite panels, giving it the better properties of both. It is known as the best building material for curtain walls.

Standard Sizes:

| Standard Sizes | Thickness | Non-Standard Sizes | Colour |

|---|---|---|---|

| 2400 x 1250 mm 3000 x 1250 mm 3600 x 1250 mm 4200 x 1250 mm |

Aluminum skin: 0.8 mm Thickness: 6, 8, 10, 12, 15, 20 and 25 mm |

Available upon request | There are more than 30 different colours to choose from, but we can also match your colour requirements. |

Characteristics:

- Light

- Flat and straight

- Fire proof

- Good rigidity

- Wind and wind pressing proof

- Sound and heat insulation

- Good intensity

- Shock resistant

- Environmentally friendly

- Easy to process and shape

- Weather proof

- Energy saving

Aluminum Honeycomb Panel Processing

Aluminum honeycomb panels can be cut, bent, sawed and routed easily by conventional tools and can be easily bonded to other objects with adhesives.

- Cutting

- Edge rounding

- Screen printing

- Sign writing

- Drilling

- Bolting

- Press forming

- Painting

- Press and fold

- Laminating

- Slotting

- Art pattern

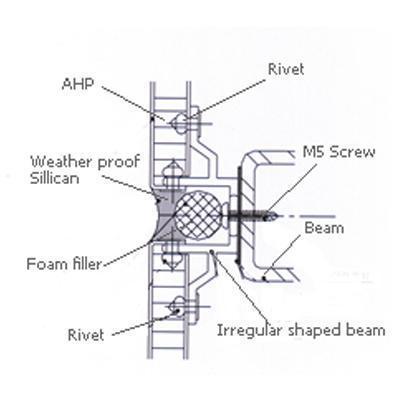

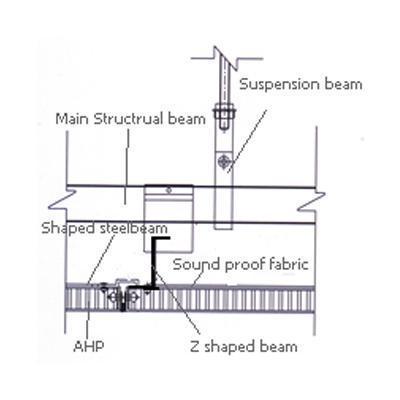

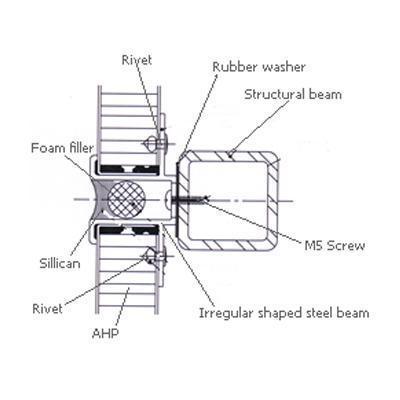

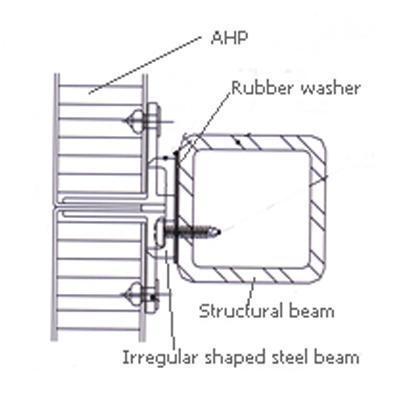

Aluminum Honeycomb Panel (AHP) Installation

The following drawings demonstrate the general AHP installation. For any particular needs or enquiries, please contact TD Cladding Supplies Pty Ltd technical support. We also provide installation services and the accessories required to complete the installation.

The accessories that are required are rubber washer, sillican gel, rivets, foam fillers, rubber seal and steel channels etc., as well as the necessary tools. TD Cladding Supplies Pty Ltd provides all of these accessories so you don't have to shop around for them yourself.

SERVICES OFFERED

TD Cladding Supplies Pty Ltd offers technical advice and fabrication services to architects, consultants, interior designers and builders.

- Tender specification for architects, designers and quantity surveyors

- We develop customised systems

- Work with architects on details and specifications

- Cut to size and fabrication

Color Range

TD Cladding Supplies Pty Ltd has more than 30 different colour products in store. We can also make custom colours to match your designs.

Technical Support

The technicians at TD Cladding Supplies Pty Ltd are available to help if you have any questions.

Warranty

We offer a 10 year warranty on any ACP and AHP panels supplied.